Are you striving to get an even coating on your products using dip coating? The lifting speed of the product from the coating liquid plays a significant role in achieving a smooth and even coating. Understanding how to adjust the lifting speed or when to use linear lifting can be challenging.

This article explains how to adjust lifting speed in dip coating and the benefits of using linear lifting.

Adjusting Lifting Speed in Dip Coating

Getting the right lifting speed is crucial for even coating thickness. Things like

the viscosity of the coating liquid, the shape of the product, and the temperature all affect the process.

1. Lifting Speed and Coating Thickness

Generally, faster lifting speeds make the coating thicker, while slower speeds make it thinner. This is because faster lifting leaves more liquid on the product.

2. Lifting Speed and Viscosity

Lifting speeds need to be slower if the viscosity of the coating liquid is high. This is because high-viscosity liquids tend to stick to the product surface, and lifting too quickly can lead to dripping and uneven coatings.

3. Finding the Optimal Lifting Speed

The best lifting speed is determined through experiments based on the liquid’s viscosity, the shape of the product, and surrounding conditions.

What Is Linear Lifting?

For curved products or high-boiling-point coating liquids, normal lifting can make the coating uneven. Coating liquid often gathers at the lower parts of the product and causes thicker coatings there. This happens because of the coating liquid’s evaporation rate and its surface tension, which cause the liquid to gather at the lower parts of the product.

1. How Linear Lifting Works

Linear lifting fixes this issue by gradually reducing the lifting speed, which ensures an even coating across the entire product.

2. Using Linear Lifting

Linear lifting is achieved by using special equipment to gradually slow down the lifting speed at a constant rate.

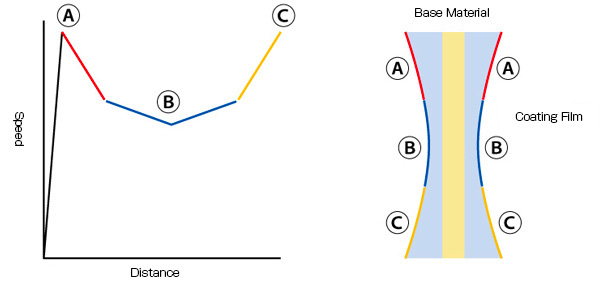

3. Illustration showing how linear lifting works.

As shown in the illustration below, linear lifting gradually adjusts the lifting speed, enabling a varied coating thickness across the product.

Summary

This article explained the adjustment of lifting speed and the benefits of linear lifting.

Adjusting lifting speed is significant for achieving even coating thickness on products. And linear lifting is particularly effective for coating curved shaped products or when using high-boiling-point coating liquids. We hope this information will be helpful in improving your dip coating process.

As a frontrunner in this field, our company uses advanced dip coating technologies to provide high-performance, CE-marked dip coaters that prioritizes safety and reliability. In addition, we provide unique machines designed for surface alignment accuracy and chemical resistance.

We also provide customization options to meet diverse needs. Contact us to find the best dip coating solution for your products!